When my cousin Carl’s daughter was little he designed a 30 pound boat built from one sheet of 10 foot plywood and two 10 foot fir 1 X 4s. It was a clever design meant to get kids out on the water under their own power. I built two of these boats, one for each son. If the boys got cranky a surefire way to cheer them up was to take the Nufs down to the water and paddle around. I found myself using it too, because it was so easy to put in the back of my pickup.

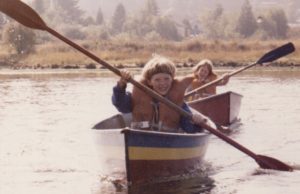

My son Ben when he was six paddling the NUF

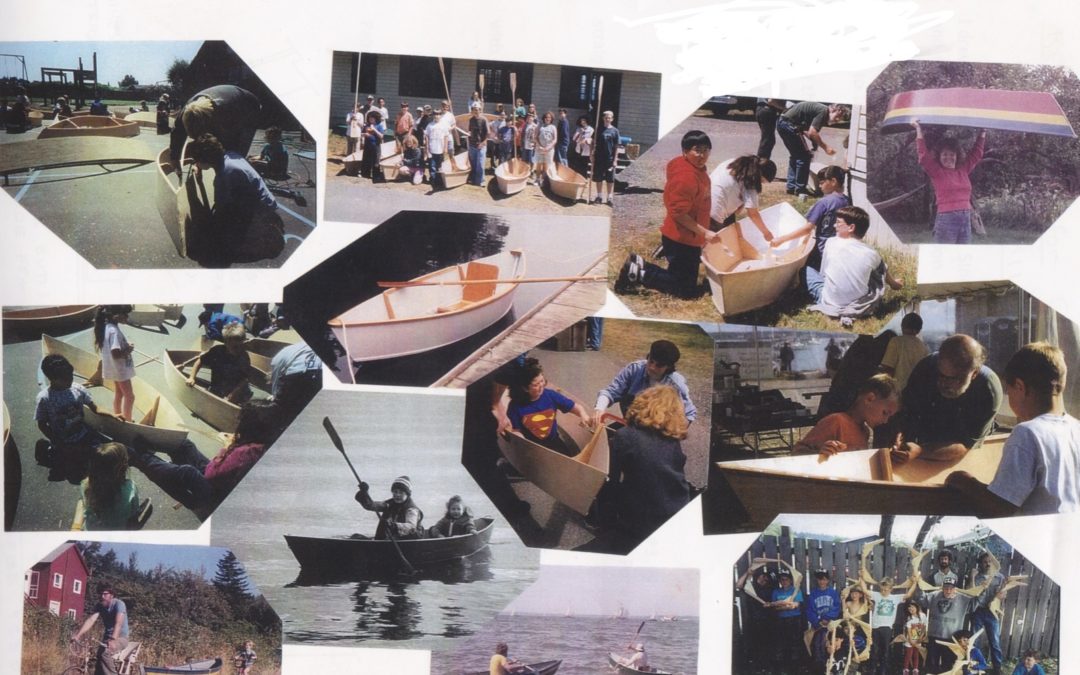

For 10 years or so Carl did family boat building at various boat events in the summer. Family boat building is where an adult, (usually, but not always mom or dad) comes with one or two kids and they build a NUF starting Friday afternoon, continuing all day Saturday and finish up Sunday by noon or so. I was lucky enough to help a couple times. It is great fun for us to help both adults and children with little or no building experience create a boat with their own labors. And empowering for them. Here are pictures from building 6 boats with 24 kids in 4 days:

A friend’s son wanted to build one so I set him up in my basement. Once he got the hull done he finished it up at home. He was in the 8th grade at the time and I pretty much told him what to do and demonstrated how to do it and left him to do it.

No boat is “easy” to build, but the Nuf is one of the easy-er boats. It’s made from one sheet of 4 X 10 plywood (if you can find it now) Here are the steps:

- The sides are 12″ wide, cut straight off the 10′ plywood.

- The frame positions are drawn on the inside of the side panels.

- The bow and stern shapes are cut in at the ends of the side panels.

- The two panels are wired together forming the sides of the boat.

- The frames are made and and inserted between the panels which results in some flare in the sides and some rocker in the bottom.

- The chine, which provides a place to nail the bottom onto, is put on the lower outside of each side panel. The chine strips are planed flat so the bottom will fit.

- Bow and stern posts made and installed.

- The bottom is glued and nailed or screwed to the chine.

- The edges are cleaned up with a plane.

- Gunwale and inwale strips are screwed and glued at the gunwale.

- Make the seat and paddle

- Plane, sand and paint and you are done. Sometimes painting is finished at home.

Here is a pretty excited kid after testing his boat:

When preparing for kids or families to build we cut the sides, which were two 12″ straight cuts off the 10′ sheet of plywood. We also cut the gunwale and chine strips (3/4″ X 1″) from 1 X 4’s beforehand to keep constructions safer and quieter. Both my sons, who went on to sail on tall ships, told me how paddling the Nuf at such an early age taught them important lessons about how boats are affected by wind and tide.

Plans are still available from Carl Chamberlin at: basicboats@cablespeed.com.

.